AutoFrost

The journey of an automated cupcake froster!

Overview

The team designed and developed an automated cupcake froster for bakeries as well as in home use. The team delivered a fully functioning alpha prototype that works via a custom mobile app, after many sessions of needfinding, prototyping, modeling and manufacturing.

Initial Steps

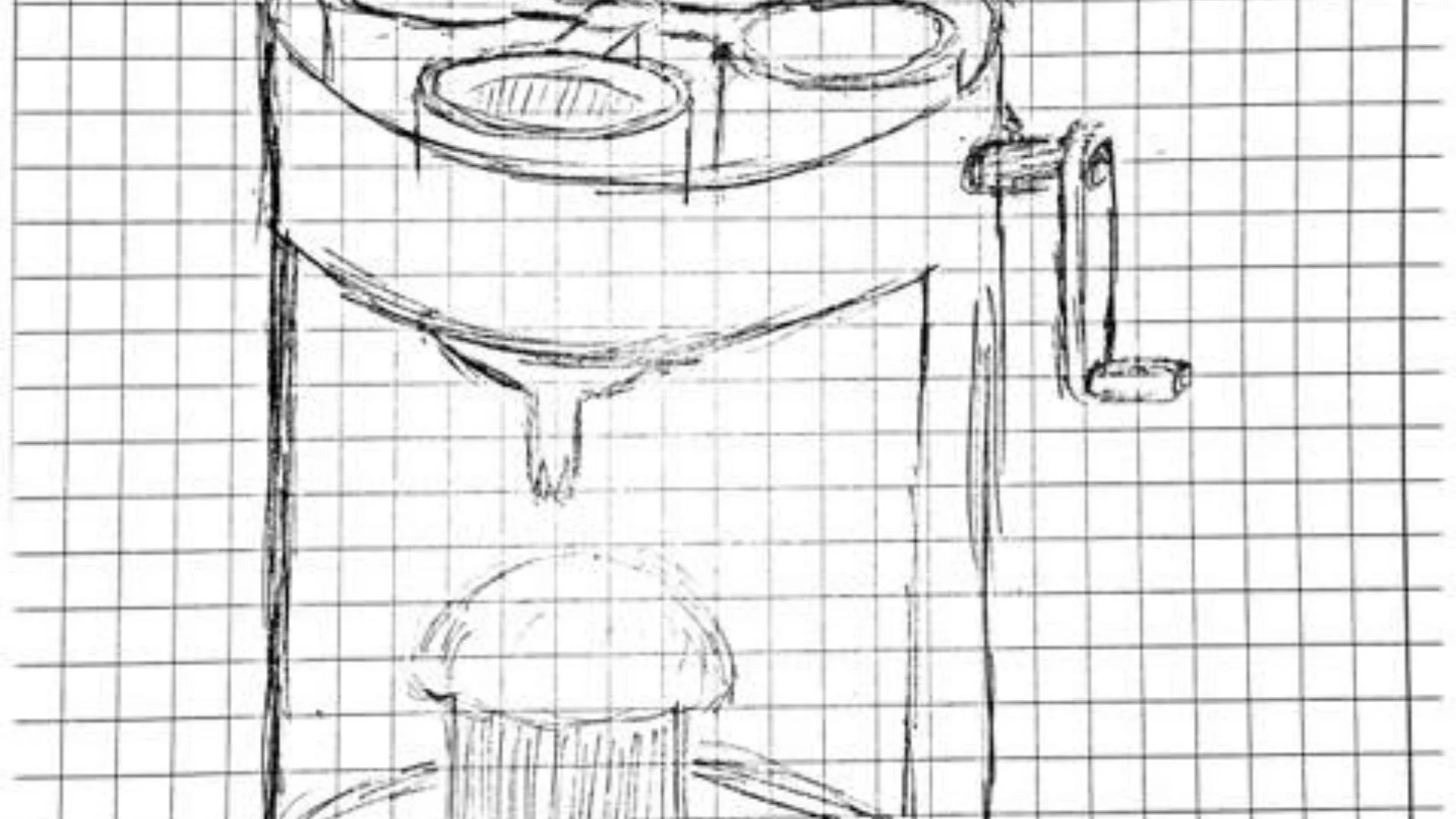

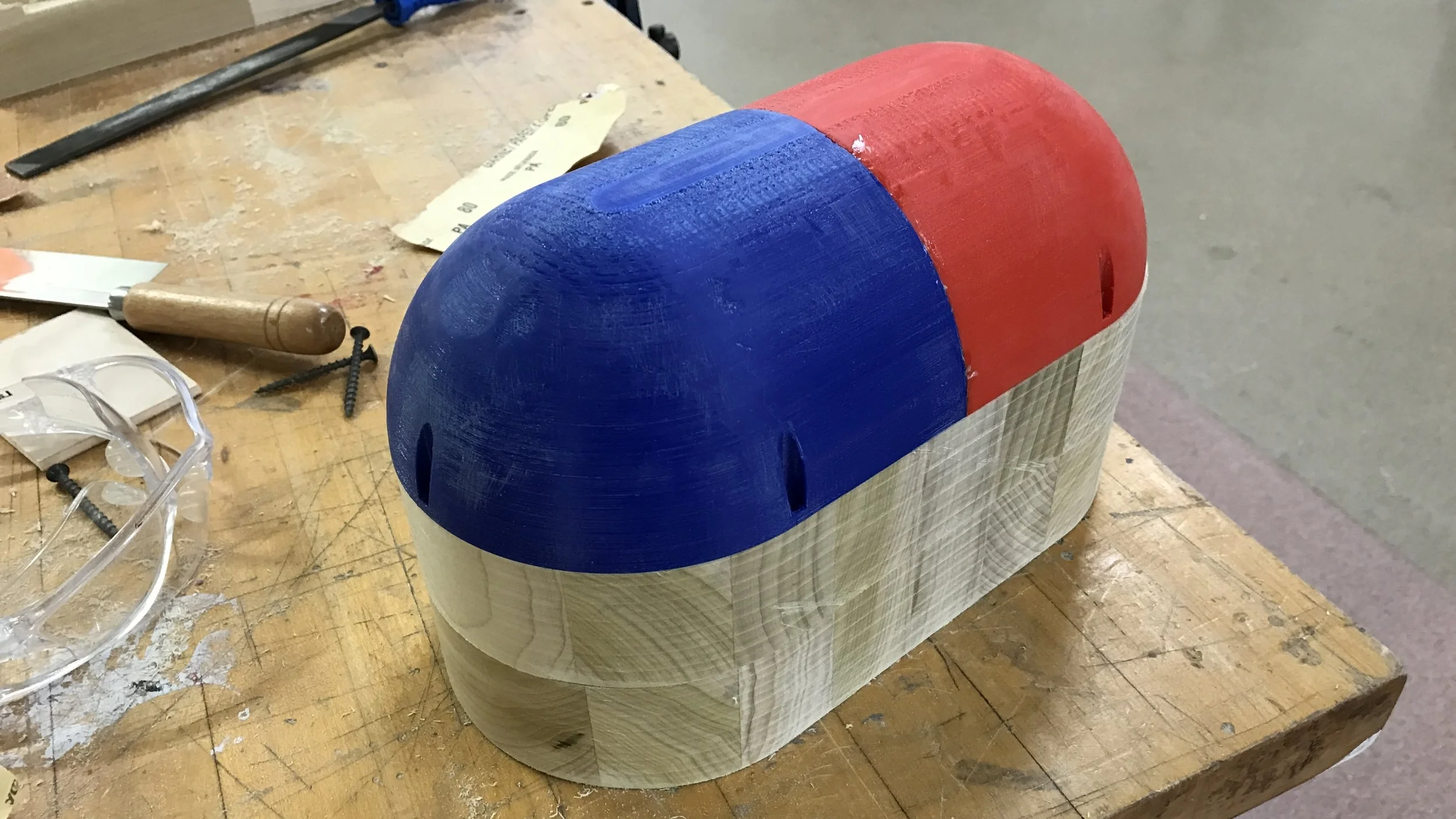

It started with problem scoping and needfinding. Once the need was found, next was to sketch different methods to satisfy the need. From the initial sketches, the team focused on creating various mock-up prototypes. With these prototypes not only the aesthetics of each design were tested, but also the functionalities were compared. The one on the left offered one dispenser to hold the frosting, while the one on the right had two containers for variety. Team settled on a design that offered only one dispenser, because the team understood that the frosting can be mixed before storing within the dispenser.

Prototyping

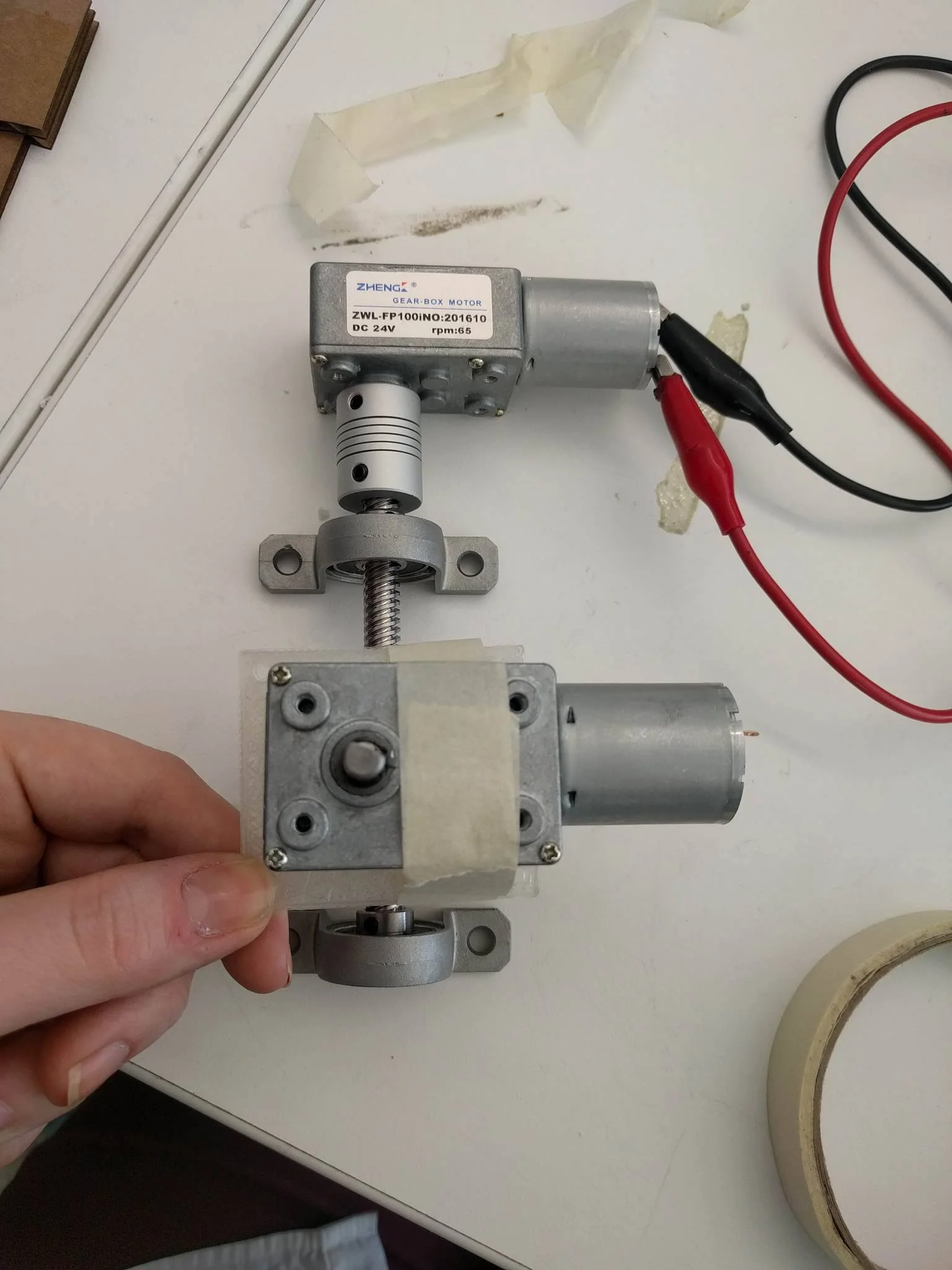

Mock-ups showed the team how the mechanisms can be designed and what our constrains look like. With these new information, the team started designing and testing the physical mechanisms. By utilizing various rapid prototyping tools such as 3D printers and laser cutters, the team tested the mechanisms and started designing the product accordingly.

Assembly

After making sure each and every mechanism functions properly, the team focused on designing and manufacturing the alpha prototype. In order to create a higher fidelity product, various parts were re-manufactured utilizing 3D printing and CNC Milling. Once everything was ready, team proceeded with the assembly of the alpha prototype.

Product

The alpha prototype is produced and tested. It frosts a cupcake not only less than 4 seconds, but also is controlled utilizing a custom mobile application designed by the team!